https://us.store.bambulab.com/products/x1-carbon-combo (Click here for link)

“Time Magazine’s Best Inventions of 2022 Award” – not kidding. A whole year of invention, but this one has changed everything.

This printer… OMG. If the world knew when this printer was going to be released, all print jobs would have stopped globally and people would have just waited until it came out to continue printing.

History

There are many interviews on YouTube from the Bambu Lab staff on this subject, the upshot is that they were looking to start a new engineering business but they didn’t know what the business should be for! As they started prototyping they realized one, inescapable truth:

The 3D printers currently available suck.

They couldn’t effectively prototype and spent just as much time troubleshooting the printer as they do printing, if not more. They decided that this was to be their new business, and the world will be grateful from that moment on.

The interview that has the best information about this was provided by The Next Layer, and is available here : https://www.youtube.com/watch?v=FaOrQD9PqNc

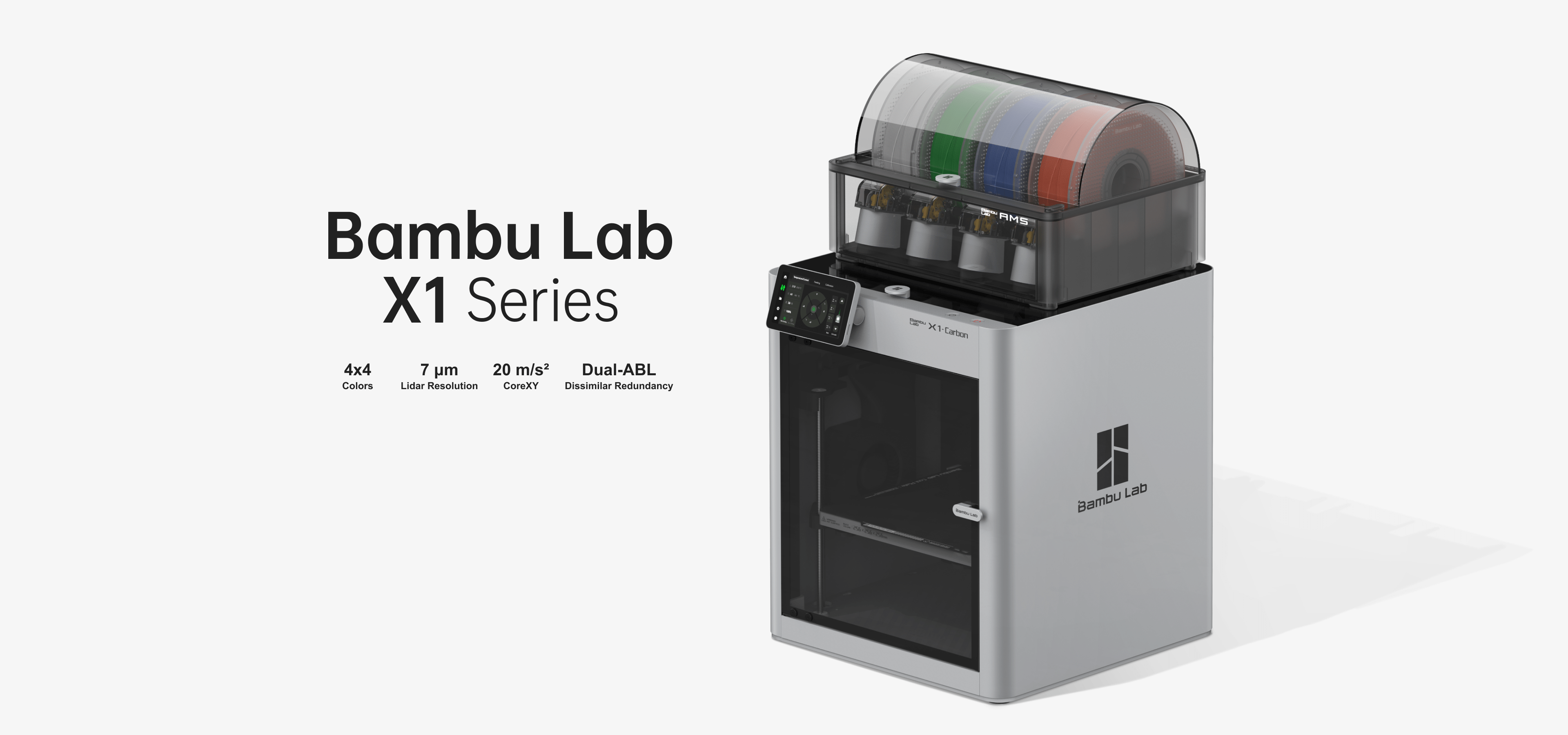

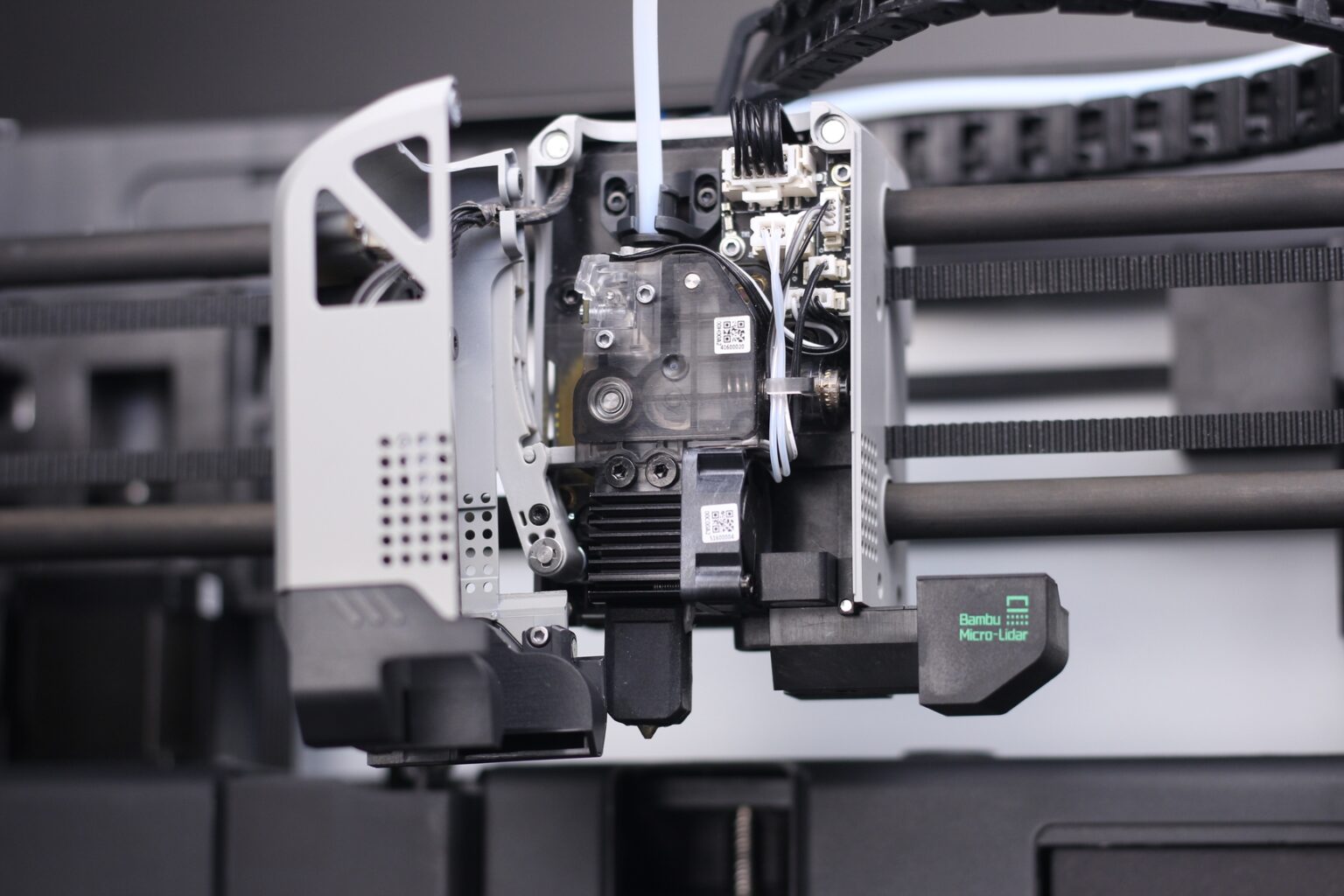

Smart Hardware, Smart Firmware

The foundation of this 3D printer is its brains – the thing is smart, and everything they advertise about it is not a gimmick:

- automatic bed leveling

- Filament jam / misfeed detection

- Jammed extruder detection

- Print bed heat problem detection

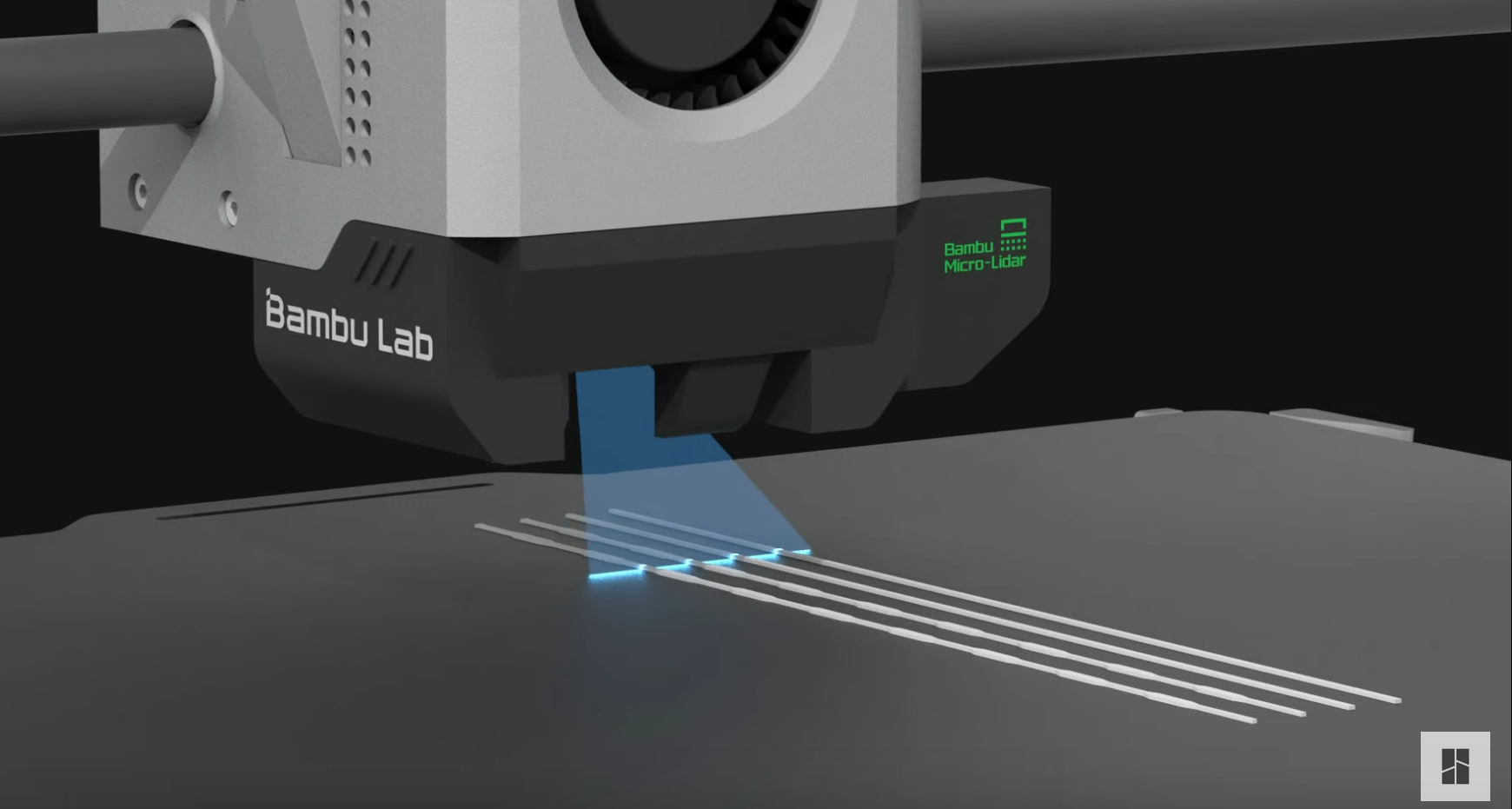

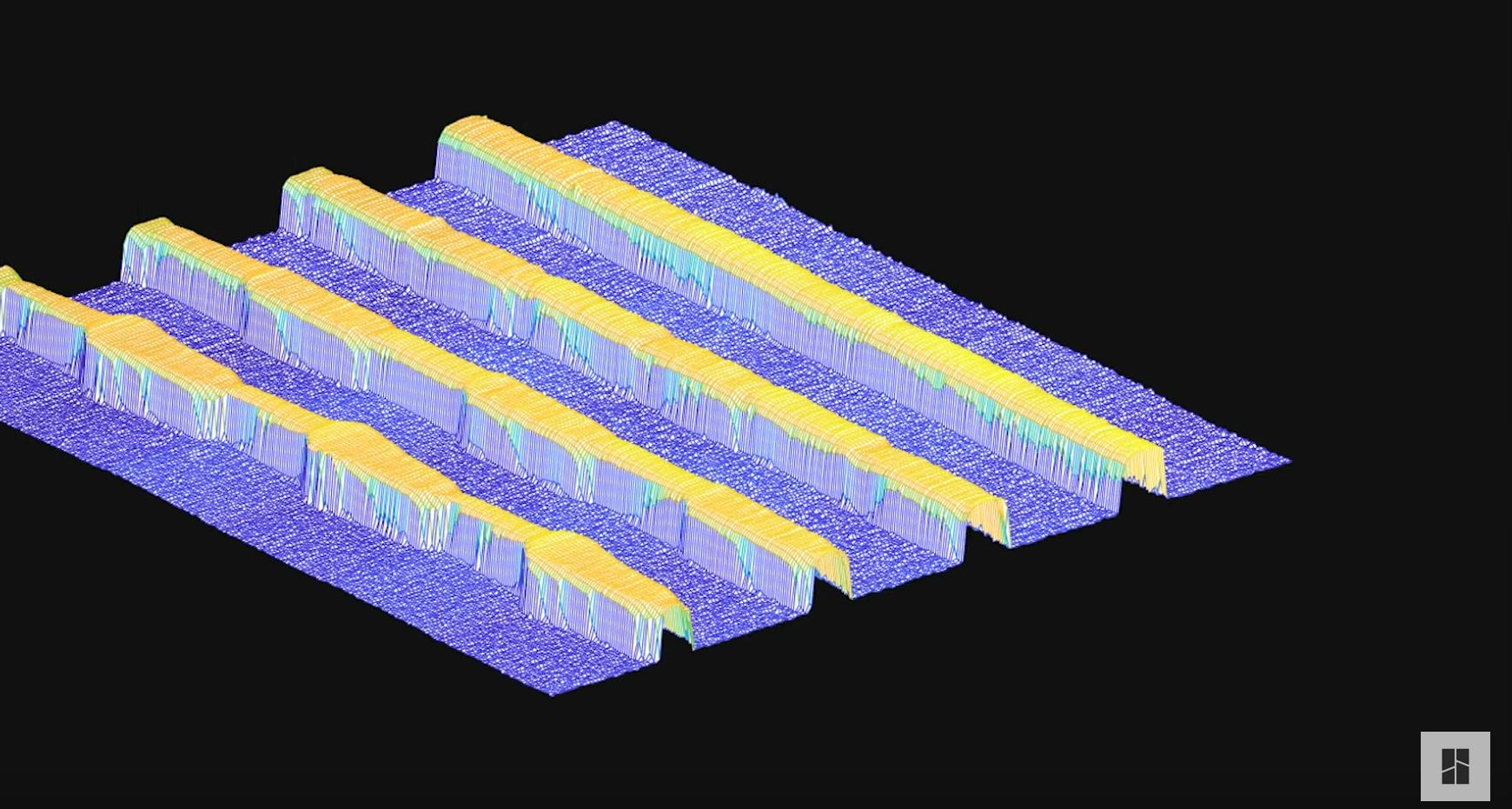

- Extrusion analysis to automatic flow rate determination

- first layer analysis

- “spaghetti monster” detection

- automatic speed vs. flow rate determination

- vibration detection, eliminating ring and echo

… and so much more. This machine is smart, automatically resolving almost every problem technicians have been struggling with ever since the first RepRap came out. The images below are accurate – it scans the first test prints and determines the settings for the best line before your print job even starts, guaranteeing not only the perfect first layer, but produces the most gorgeous Benchy I’ve ever seen.

Problem with the filament? It’ll tell you if it can’t self-correct. Has it been a while since you cleaned it? It’s okay, it’ll give you a reminder to perform maintenance – and tell you how! These “features” work, this printer has your back and you can depend on it.

Reliabiilty

This software and hardware intelligence has improved the reliability of 3D print jobs dramatically. Between ABS, Carbon Fiber, TPU and even water-dissolving supports, the probability of a print job being successful is near-certain, and you can switch filament trivially.

In point of fact, if you load ABS, Carbon Fiber and wood filaments into the auto-feeder (“AMS”), it’ll know it’s dealing with a different filament in-situ and adjust temperature, speed and print details (such as layer height) automatically. Your work was done the moment you loaded the filament.

Speed

After resolving reliability issues comes speed, and holy cats is this thing fast! It’s like something you’d expect to see in a space station, busting out a critical part ASAP while you’re losing atmosphere… It’s so fast it’s just a blur, well past a human’s ability to, say, reach in with a pair of tweezers and pull a rogue strand of filament out of the way of the print head: you will never, ever move fast enough not to get in the way of this thing while it’s printing.

This blinding speed blows me away. How do you get molten Carbon Fiber to properly align that fast? When printing wood, why doesn’t the filament smear, and how can anything melt together at speed without melting too much, or not enough?

I’m here to tell you I didn’t believe it, but it can, and it does, and it’s amazing. Sometimes I just stare at it and watch it print, thinking “You’ve gotta be kidding me”.

The coup de grace? I’m referring to its *normal* speed. It can print faster (“Sport”, 125%) or even faster (“Ludicrous”, 166%). One would think the wheels would come off the bike if you move that fast but not only does this smart machine automatically adjust for the speed, some filaments actually print better at Sport or faster. Wood filament for example will “leak” chemicals over time, clogging up your extruder to the point that you simply have to replace it. This thing can blow the filament through so fast it doesn’t have a chance to leave chemicals behind – you can just watch the spool turn as it throws filament down faster than anything you’ve ever seen.

The following video is from YouTube, and shows a time lapse of an elaborate 4-color print job. Prints such as these are touted as exceptional, but for the X1 Carbon with an AMS, it’s just another day at the office. The white “trees” are for support and by default are automatically generated by the slicer software where needed… or you can “paint” the supports in where you want them by hand.

“No More Slinging the Print Bed Around”

The CEO of Bambu made a very keen point – the design of this printer made the extruder ultra-light, and the print bed only goes up and down. This is part of where the speed comes from: the guide rails are carbon fiber, the print head extremely light weight and the heater is ultra-small ceramic (yet heads 10 degrees centigrade every second – that little heater works). They did need to apply custom parts, doing away with the Prusa, Makerbot and Creality standards entirely, but this is a good thing. Replacing a standard print head takes an hour-ish, but on this device it takes 10 minutes and your work will be perfectly reliable since it self-calibrates afterwards.

Clever Build Plate

Bambu Lab did something different with the build plate, in that it’s spring steel that adheres to the bed magnetically. While this has been done before – flexible, removable build plate – the material it’s made of combined with the removable and replaceable PLA surface makes it brilliant. The adhesion is excellent, reliable, and retrieving your print job is trivial.

Speaking of adhesion, have you ever had to use glue on the build plate not to adhere, but to help release the print?! Put another way, you don’t use glue to help the plastic stick because without gluestick, it sticks too well and is a super bitch to get off. I think this speaks well of the build plate design and construct.

Cheap Parts (In a Good Way) & Good Filament

You read the above right, almost all the parts are proprietary and have to be ordered from Bambu directly. This has potential to be a serious problem… but it hasn’t been. Not only does the printer already come with the most common spare parts you need anyway, but if you need another print head it’s only $15. A year’s supply of their liquid “glue stick” for the bed is $10. A bag of ceramic heaters is another $14. All these parts ship quickly and can even be purchased directly from their mobile app.

Filament is a “part”, and Bambu keeps their cost down not by selling crap filament but by having you use the filament it came with to print a new, reusable spool! Their excellent, high-quality filament comes raw, easily installed into a spool that you print and can re-use.

The best part? Their filament spools have RFID chips which are automatically read by the AMS media-switching system. When you load the spool and load it into the AMS, it knows what the filament is – type, color, temperature, speed and any other characteristics – and prints accordingly, automatically.

I’m telling ya, the world’s never seen anything like this before now, and it’s not a gimmick – it works every hour of every day, all day.

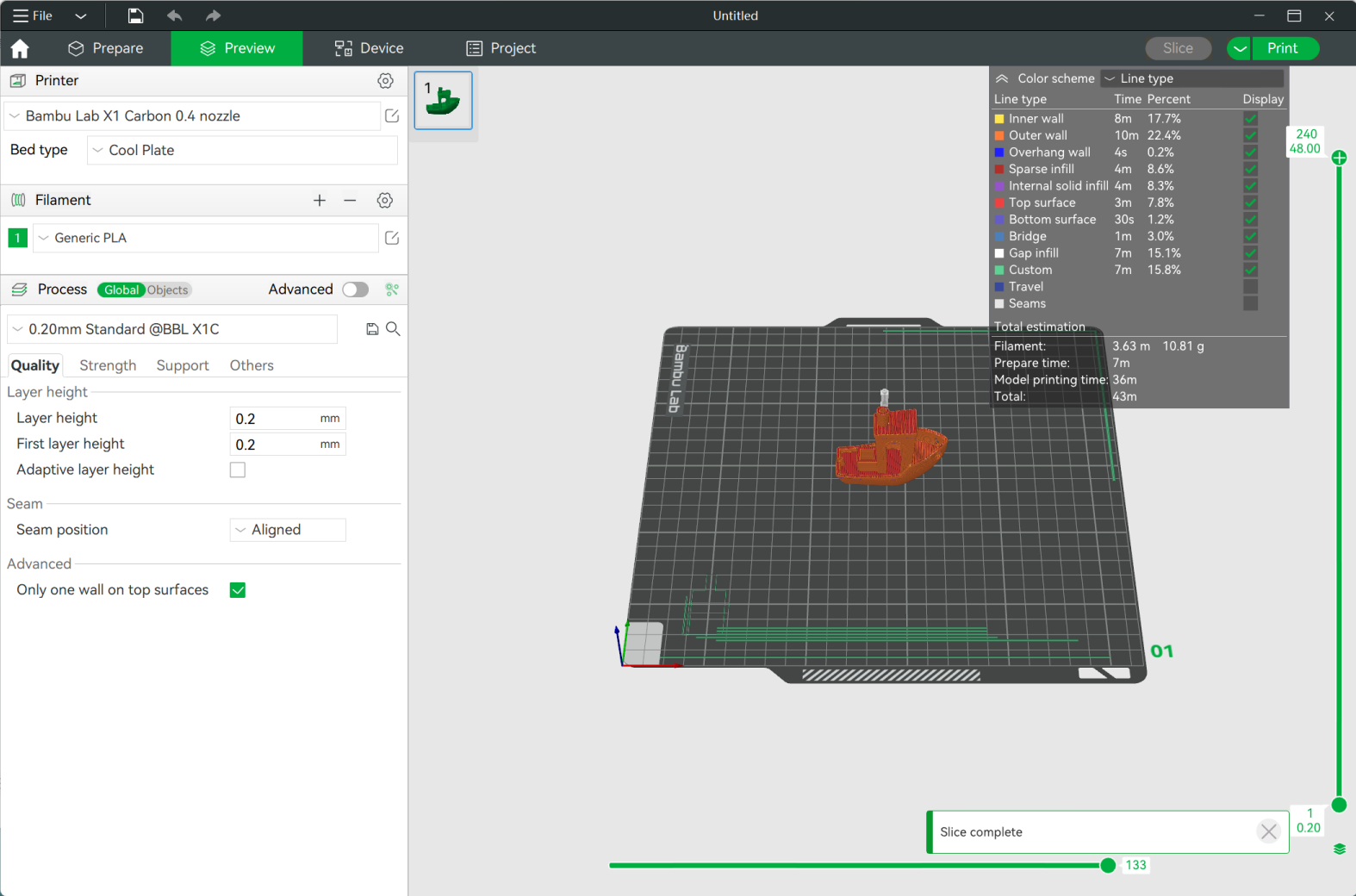

Slicer Software

Bambu has caught some crap for requiring use of their own slicer software instead of relying upon tried-and-true, such as Cura, Prusa or Simplify3D.

It was the right thing to do, though.

If you need to print ABS, you need to flip the magnetic bed over, and the slicer software will tell you if you forgot to do that.

Are you manually loading filament… only to forget to clear the way for the auto-feeder? It’s okay, it’ll tell you before it starts to print.

Consider the fact that speed is related to material volume and temperature – if the software and hardware automatically figure these things out then you could remove over half the options in the slicer software, and they did! This simplifies printing dramatically – you load your object into the slicer and it does the math. You select the filament and send it to the printer and it’ll be done before dinnertime is over. No more memorizing option after option after option – it figures this stuff out itself. Given the screenshot above, you can select Advanced mode, but it’s unnecessary 80% of the time.

Lastly, their slicer software notably handles supports better, as well as multiple colors and color “painting”. Bring the object in from printables.com and the software will automatically correct any flaws, then you can “paint” different parts different colors, and then bust it out on the printer. You usually won’t need any additional software unless you’re custom making a part.

“Bambu Handy”

In the international market, your cell phone is called a “handy”. Bambu Handy is a mobile app – like their slicer software, it’s a proprietary app that interfaces with the hardware to deliver real-time status of your printer and print job. It’s powerful and affective, and if you find yourself running out of filament you can purchase parts from the app, too.

I generally don’t like apps for system control and shopping, but the integration is tight – it knows your printer type and model, knows what it needs and filters your selection based on that, so that you only see and can order what fits your printer.

Brilliant.

Cloud or Local?

When the printers first came out they also caught grief for sending all print jobs through a cloud print broker, eliminating privacy.

This has since been corrected, and users now have the option of printing directly to printer over network, using an SD chip to load the project file OR using the cloud service.

Easy to Repair

All 3D printers have some tech mess – you need to clean the extruder or replace it, replace a fan, clean up the print bed, etc, etc. This is why 3D printers have been relegated to a technical audience, because if you get a good print job out, you now need to maintain the printer too, and it’s a serious pain in the ass.

The Bambu X1 Carbon breaks this standard – shatters it, actually. On my Tenlog TL-D3 Pro which uses all industry-standard parts, I have to remove 6 screws to access the extruder, replace it carefully, install it carefully, and then spend the next hour (or three, depending) recalibrating the printer and level. It’s a horrific PITA.

Replacing the print head on the X1 Carbon involves 2 screws and takes 10 minutes, it’ll even display a QR code for the video to walk you through the steps. When done, it’ll self-calibrate and self-level by the time you’ve made a cup of tea and be done when you return to sit down to watch it. Bust out a new Benchy to crosscheck while you drink your tea and you’ll be printing again before you finish the cup.

The image above is from 3dprintbeginner.com , who also did a review but it’s much more thorough than this one, I’d highly recommend giving it a read: https://3dprintbeginner.com/bambu-lab-x1-carbon-review/

Drawback: Loud!

There are a few drawbacks to this device, the first of which is its audio volume. You’re not sleeping in the same room as this printer, especially if it’s in Sport or Ludicrous speed. It whips the print head around so fast that between that and the fans – even within the enclosure – you’re in a construction zone, and it sounds like it.

If you print slowly and have no filament swaps, it’s not so bad.

Drawback: Waste

If you use the AMS to swap filament, it’ll have to retract, feed the new and then purge the previous color with every layer, and there are often thousands of layers.

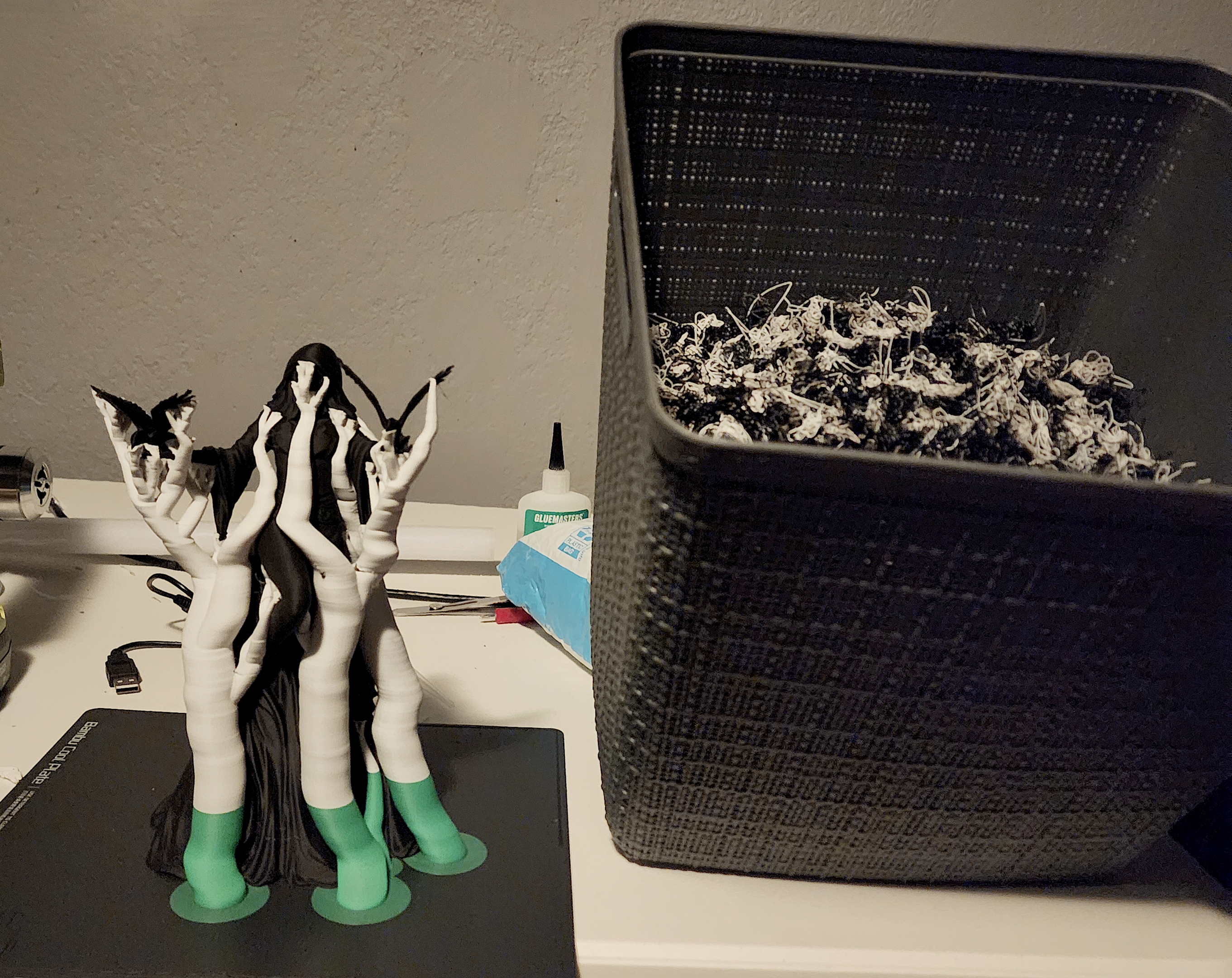

I printed a figurine of Nocturnal (pictured below) out of three colors (matte black, shiny black, support filament), which my standard Crealilty-type printer couldn’t even think about doing. I had it stop at night and resume printing in the morning (no problem for this printer) so it completed 4 days later and was perfect… but I had a pile of waste larger than the figurine itself! It stands to reason, in that it automatically determines where to put what drop (or stripe) of color with zero bleed between them so a white and black object will have no gray, and regardless of what the filament details are you won’t get clogs mid-print because it does such a good job of cleaning, but oh man you will get waste.

It has a waste chute in the back – otherwise known in community as the “poop chute”, and it does “poop” a great deal. The Spider Man video above surely generated a small trashcan of filament waste and you can see how much the figurine pictured below generated:

Still, if I had to choose between reliability and sparing every inch of filament I’d choose reliability since this device will print for a full week straight without skipping a beat.

Can you imagine this failing 3 days into the print?

I’ll pay a “poop tax” for that.

Conclusion

There are reviews all over the Internet as people pontificate over their own experiences and think that everyone needs to know about their experiences with their purchase… how sick are we of hearing what other people think?

I write this article not because my perspective and experiences have inherent value, but because the world should know 3D printing is no longer what it was. The advent of this technology has already had a resounding affect to the 3D printing community to the point that “greybeards” in 3D printing are frustrated that people brand new to printing can bust out an object better than they can several times faster yet have absolutely no concept how their 3D printer can do what it does. They feel they haven’t paid their “experience tax” and are too “n00b” to even ask questions on forums about their printer. Seriously, people are getting angry about it.

These experienced 3D professionals are getting angry because all the work they had to do – hours and hours and days and days of bullshit work, figuring things out and crafting custom solutions – is no longer necessary. My 80 year old mother can print a new planter for her plants, no big deal, no support, no problem, and the planter will look better than anything these “greybeard” pros can produce.

That’s worth blogging about.

To quote another 3D printing professional, “Where has this thing been all my life?”